Blog

Two containers of goods are being shipped today...

Our Brazil customer ordered two containers of goods successfully completed and passed the customer's strict quality inspection. Please enjoy the following product photos:

1. Curved shackle nut and cotter pin (G2130) Finish: Hot dip galvanized

2. Curved Shackle Threaded Pin (G209) Finish: Hot dip galvanized

3. Straight shackle threaded pin(European Type Large D Shackle) Finish: Electrolytic galvanized

(2)_1000.jpeg)

(1)_1000.jpeg)

4. Grade 8 Chain connector link Finish: Yellow epoxy paint

_1000.jpeg)

5. Grade 8 Strap connector link Finish: Yellow epoxy paint

_1000.jpeg)

6. Grade 8 Clevis Hook with Safety Latch Finish: Yellow epoxy paint

7. Grade 8 Clevis shortening hook Finish: Yellow epoxy paint

8. Grade 8 Safety latch eye hook Finish: Yellow epoxy paint

9. Grade 8 Forged ring (A-342) Finish: Yellow epoxy paint

_1000.jpeg)

(2)_1000.jpeg)

10. Grade 8 Ring with long sub-links (A-347) Finish: Yellow epoxy paint

(3)_1000.jpeg)

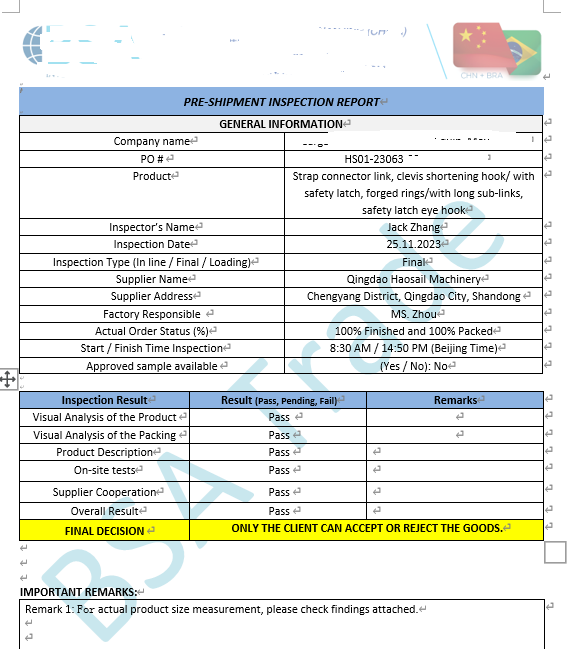

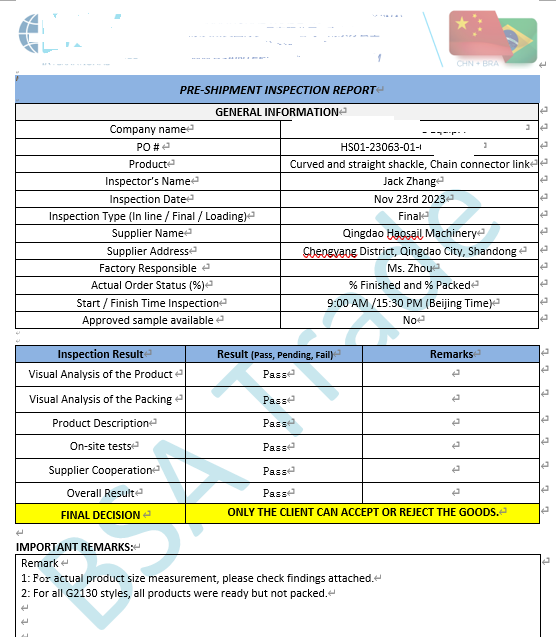

Customer's third party inspection pass report

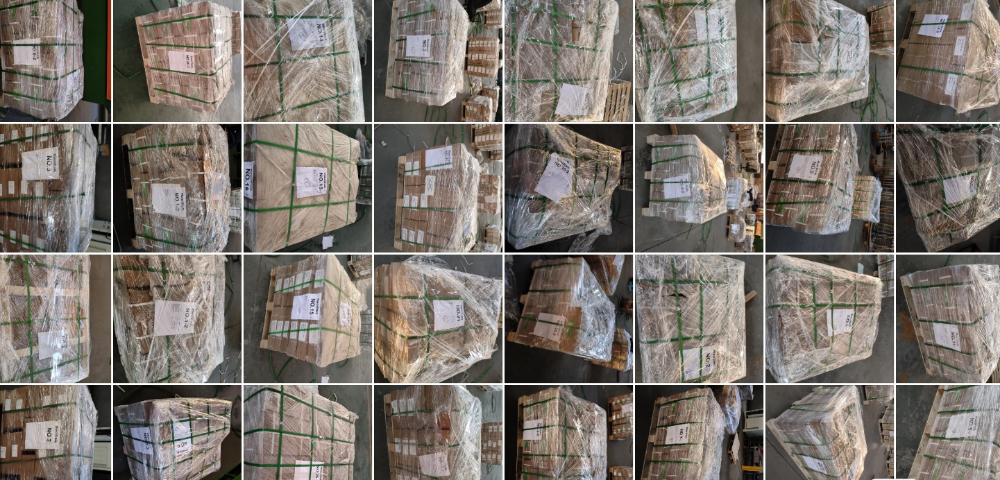

Packaging

A carabiner hook, also known simply as a carabiner, is a specialized type of metal loop with a spring-loaded gate that is designed for quick and secure attachment. It is commonly used in various applications where a strong and reliable connection is needed.

Carabiner hooks are typically made of aluminum or steel and come in different sizes, shapes, and weight capacities. They are widely used in outdoor activities, sports, and industries such as climbing, camping, hiking, boating, and more.

The design of a carabiner hook allows for easy attachment and detachment of items. The gate, which is the hinged part of the carabiner, can be opened by applying pressure to the gate and then closed by releasing the pressure, causing the gate to spring back into its closed position. This mechanism provides a secure closure that helps prevent accidental openings.

Carabiner hooks are used for a variety of purposes depending on the specific application. In outdoor activities like climbing, they are commonly used to connect ropes, harnesses, and other climbing gear. They can also be used to attach gear to backpacks, secure tarps or tents, hang items, create temporary anchor points, or organize equipment.

When using a carabiner hook, it's important to ensure that the gate is properly closed and locked. This helps prevent unintentional openings and ensures a secure attachment. It's also important to check the weight capacity and intended use of the carabiner to ensure it is suitable for the load or activity.

It's worth noting that carabiner hooks come in different shapes, such as D-shaped, oval-shaped, or pear-shaped. Each shape has its own advantages and may be suitable for specific applications or preferences.

It's essential to use carabiner hooks within their intended capacities and follow proper safety guidelines to ensure reliability and prevent accidents or failures. Always consult the manufacturer's instructions and guidelines for the specific carabiner hook you are using.

Blocks and pulleys are mechanical devices used in sailboat rigging and various other applications to change the direction of a line or rope and provide mechanical advantage. They consist of one or more sheaves (wheels with a grooved rim) mounted within a frame or housing.

Here are some key aspects of blocks and pulleys:

Sheave: The sheave is the wheel or grooved rim within the block or pulley. It is designed to minimize friction and allow the line to move smoothly. The sheave can be made of various materials such as metal, plastic, or ceramic.

Frame or Housing: The frame or housing of a block or pulley holds the sheave in place and provides support. It is typically made of metal, such as stainless steel or aluminum, for strength and durability.

Attachment Points: Blocks and pulleys have attachment points for securing them to a fixed point or connecting them to other rigging components. These attachment points may include an eye, shackle, or becket.

Single, Double, and Triple Blocks: Blocks and pulleys come in different configurations. Single blocks have one sheave, double blocks have two sheaves side by side, and triple blocks have three sheaves. Multiple-sheave blocks increase the mechanical advantage by distributing the load over multiple lines, allowing for easier and more efficient line handling.

Fixed and Swivel Blocks: Fixed blocks have a stationary frame, meaning they only rotate around the axis of the sheave. Swivel blocks, on the other hand, have a rotating frame that allows the block to rotate freely, providing greater flexibility in line direction.

Becket: Some blocks have a becket, which is a small metal post or extension on the block's frame. The becket provides an additional attachment point for lines, allowing for more versatile rigging configurations.

Blocks and pulleys are used in numerous sailing applications, such as halyards (to raise and lower sails), sheets (to control sail trim), control lines (for sail controls like reefing or vang), and other rigging systems. They are also used in various non-marine applications that require mechanical advantage, such as lifting and hauling systems.

When using blocks and pulleys, it's important to select the appropriate size, strength, and configuration based on the intended load and application. Regular inspection and maintenance, including lubrication of the sheaves and checking for wear or damage, are essential for ensuring their proper functioning and longevity.

Note that the specific usage and placement of blocks and pulleys in a sailboat rigging system may vary depending on the boat's design, the type of sailing, and individual preferences.

A carabiner, also spelled "karabiner," is a specialized type of metal loop with a spring-loaded gate. It is commonly used in outdoor activities, sports, and various other applications that require secure attachment or quick release of items.

Carabiners are typically made of aluminum or steel and come in various sizes and shapes, but they generally consist of a curved or D-shaped body with a hinged gate that can be opened or closed. The gate is usually spring-loaded, allowing it to close automatically when released.

Carabiners are widely used in activities such as rock climbing, hiking, camping, and mountaineering. They serve as a primary means of connecting ropes, harnesses, and other equipment to ensure safety and secure attachments. They can be used to connect a climber's harness to a rope, to secure gear to a backpack, or to create temporary anchor points.

In addition to outdoor activities, carabiners are also used in various other settings. For example, they may be used for keychains, attaching water bottles to backpacks, securing equipment during transportation, or organizing items in workshops or garages.

It's important to note that not all carabiners are designed for climbing or load-bearing purposes. Carabiners used for climbing and other critical applications should meet specific safety standards and have a high strength rating. Always check the intended use and load rating of a carabiner before using it to ensure it is appropriate for the task at hand.

When using a carabiner, it's crucial to ensure that the gate is properly closed and locked to prevent accidental opening. Regular inspection of the carabiner for signs of wear or damage is also important to ensure its reliability and safety.

Please keep in mind that while carabiners are versatile and widely used, it's important to follow proper safety guidelines and use them within their intended capacities to avoid accidents or failures.

- 2025

- 2024

- 2023

- 2022